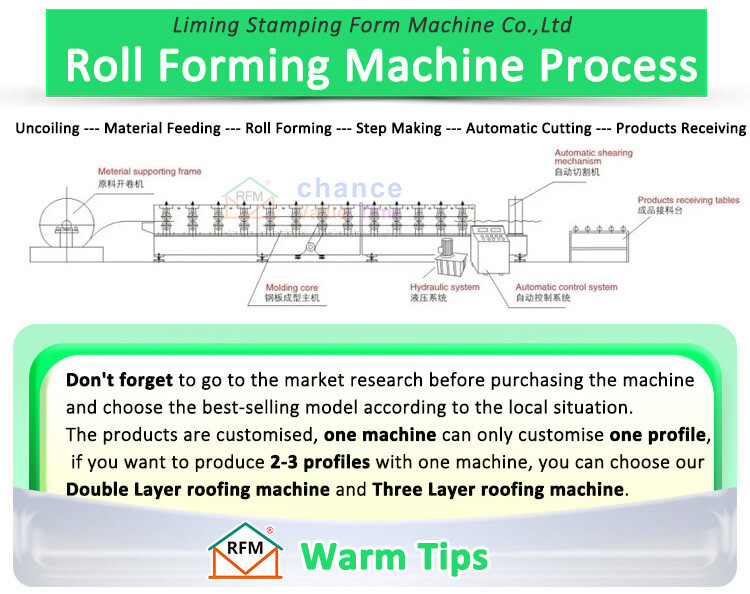

1. Overview of the Metal Roofing Machine

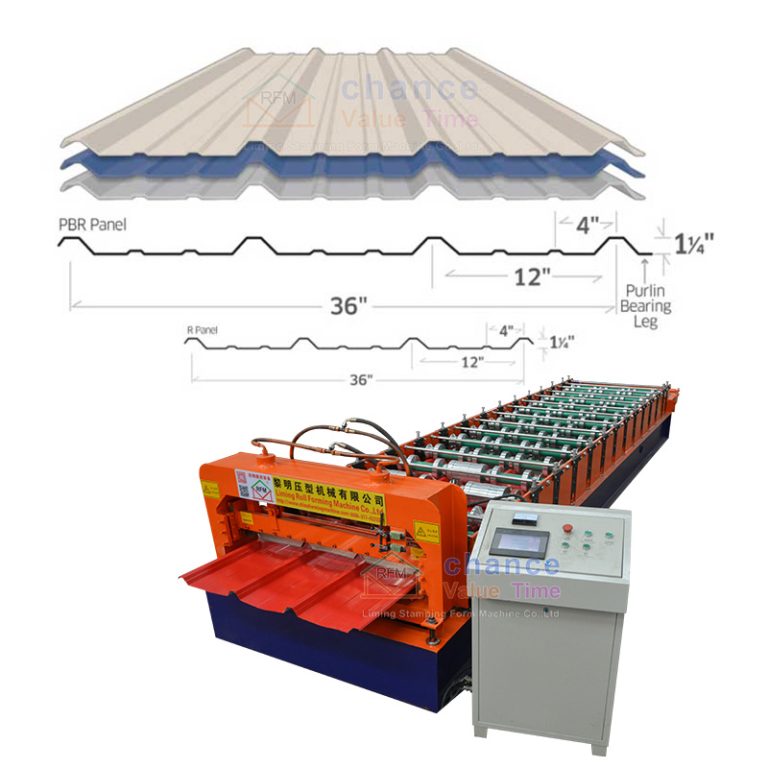

Our Metal Roofing Machine is an advanced roll forming system designed for continuous and automated production of roofing sheets. With a robust frame, precision rollers, and an intelligent control system, it guarantees consistent and accurate forming of various roofing profiles. The machine is suitable for a wide range of materials, including galvanized steel, aluminum, and coated metal sheets, allowing for versatility in production.

Equipped with automatic cutting, high-speed operation, and an easy-to-use PLC control system, our machine minimizes downtime and maximizes efficiency. Manufacturers can produce roofing panels in different shapes and sizes, including corrugated, trapezoidal, and standing seam profiles, catering to diverse market needs.

2. Key Features and Benefits

High-Speed and Efficient Production

- Our machine operates at an impressive speed, ensuring continuous forming and cutting of roofing sheets.

- Reduces production time and increases output capacity, making it ideal for large-scale manufacturing.

Precision and Consistency

- Advanced roller design ensures accurate profile formation with minimal material waste.

- High-quality hardened rollers maintain shape precision, reducing errors in roofing panel dimensions.

Robust and Durable Construction

- Built with heavy-duty steelto withstand long-term use and harsh industrial environments.

- Corrosion-resistant components extend the machine’s lifespan and maintain high performance.

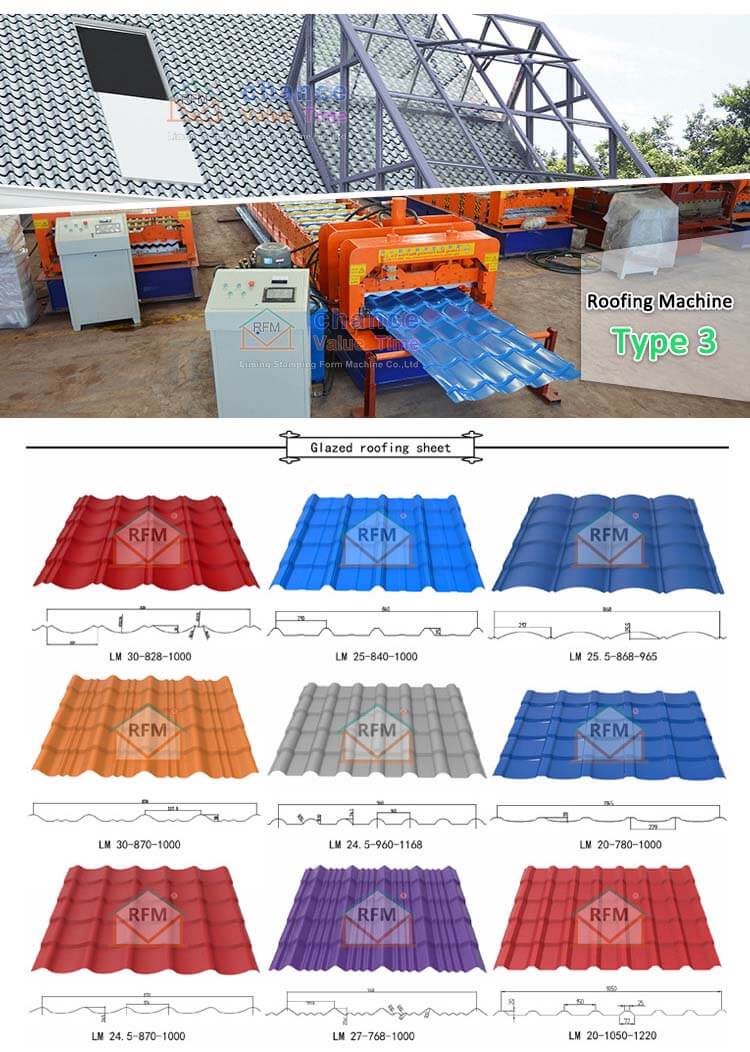

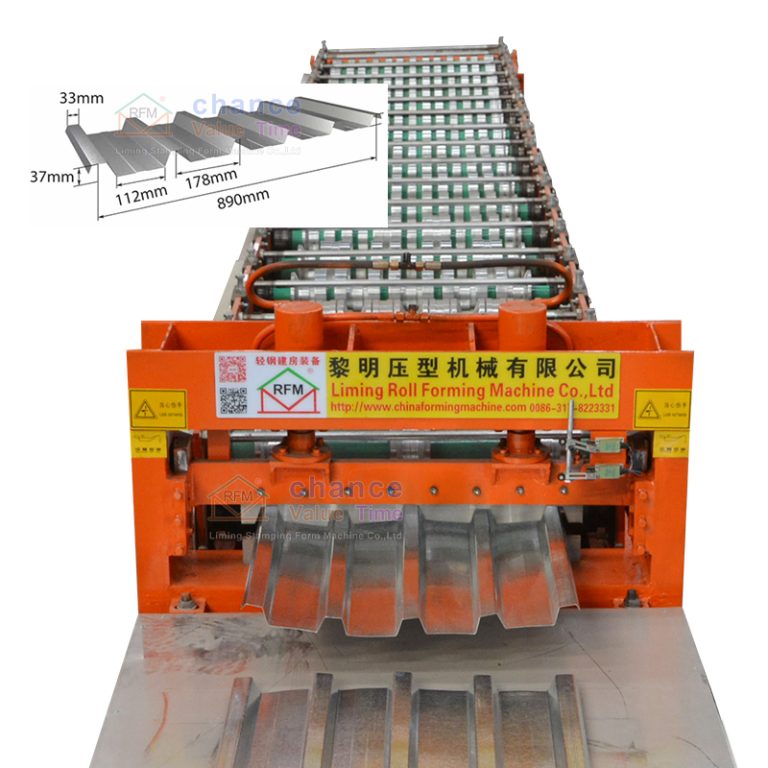

Customizable Roofing Profiles

- Supports various metal roofing designs, including corrugated, trapezoidal, and standing seam panels.

- Adjustable settings allow manufacturers to produce different sheet sizes based on customer requirements.

Automatic Cutting & Stacking System

- The hydraulic or servo-driven cutting system ensures smooth, precise, and burr-free cuts.

- Automated stacking reduces labor costs and improves workflow efficiency.

User-Friendly PLC Control System

- The machine is equipped with an intelligent PLC control panelfor easy operation.

- Allows quick adjustments to sheet length, profile design, and cutting parameters.

Energy-Efficient and Cost-Effective

- Low power consumption without compromising performance.

- Reduces operational costs, making it a sustainable investment for metal roofing manufacturers.

3. Applications of Metal Roofing Panels

Our Metal Roofing Machine is suitable for producing roofing panels used in various industries, including:

Commercial Buildings – Warehouses, factories, and shopping malls.

Residential Homes – Modern and traditional housing projects.

Agricultural Structures – Barns, farmhouses, and storage facilities.

Industrial Facilities – Power plants, steel plants, and industrial sheds.

With the ability to produce high-quality, durable, and weather-resistant roofing panels, our machine is widely used in global construction projects.

4. Why Choose Our Metal Roofing Machine?

We take pride in our extensive experience and expertise in roll forming technology. Here’s why our Metal Roofing Machine stands out in the market:

Over 29 Years of Industry Experience – A trusted name in roll forming machine manufacturing.

Global Presence – Supplying machines to customers in Russia, Turkey, Egypt, Italy, Brazil, and beyond.

Comprehensive After-Sales Support – Professional guidance, installation services, and technical assistance.

High-Quality Components – Only premium-grade materials and advanced technology are used.

Competitive Pricing – Offering the best value for high-performance machinery.

5. Technical Specifications

| Feature |

Specification |

| Material Thickness |

0.3mm – 0.8mm |

| Forming Speed |

10 – 25m/min |

| Roller Material |

High-grade steel with hard chrome coating |

| Cutting System |

Hydraulic or Servo Cutting |

| Control System |

PLC with Touchscreen Interface |

| Power Requirement |

380V, 50Hz, 3-phase |

| Machine Dimensions |

Customizable based on requirements |

6. Conclusion

If you are looking for a high-performance, durable, and cost-effective Metal Roofing Machine, we have the perfect solution for your business. Our machine is designed to deliver superior quality roofing sheets with precision, efficiency, and flexibility. Whether you are an established manufacturer or expanding into the metal roofing industry, our machine will help increase production efficiency, reduce labor costs, and improve product quality.

Contact us today to learn more about our Metal Roofing Machine and get a customized quote!