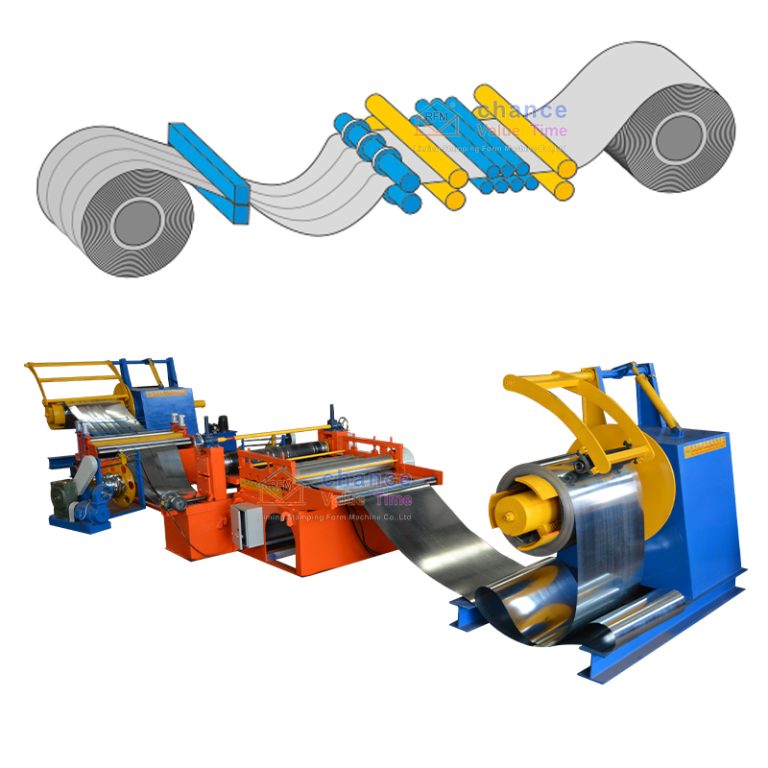

- Structure and Components

A typical slitting line production line consists of multiple integrated systems:

- Uncoiler: Responsible for unwinding the metal coil material.

- Straightening Machine: Ensures the flatness of the strip to prevent deformation.

- Guidance System: Accurately aligns the material for precise cutting.

- Slitting Unit: Equipped with disc shears to longitudinally cut the strip into specified widths.

- Edge Waste Collector: Collects and winds the trimmed edges.

- Tension Control System: Maintains consistent tension during the process to avoid material stretching or wrinkling.

- Recoiler: Rewinds the divided strips into small coils for subsequent processes.

- Hydraulic and Electrical Control System: Manages overall automation and adjustments.

- Working Principle

The production line operates through a coordinated sequence:

1.Loading: The metal coil is placed on the uncoiler by an automatic feeding system.

2.Uncoiling: The coil is unwound, and the strip is guided through the straightening machine.

3.Shearing: Disc shears longitudinally cut the strip into multiple parallel strips based on preset widths.

4.Waste Management: Scrap edges are automatically collected.

5.Rewinding: The separated strips are wound into individual coils under controlled tension.

6.Discharge: Finished coils are unloaded for further processing.

- Key Features and Advantages

- High Precision: Disc shears ensure minimal burrs and dimensional accuracy.

- Efficient Material Utilization: Optimizes strip width allocation to reduce waste.

- Versatility: Handles various materials (e.g., cold-rolled steel, silicon steel, stainless steel, aluminum) and thicknesses (0.1-6.0mm).

- Automation: PLC control and servo drives enhance efficiency, minimizing manual intervention.

- Adjustable Speed: Variable cutting speeds (up to 200m/min) adapt to different production requirements.

- Safety and Durability: Robust machine frame and overload protection systems ensure stable operation.

- Applications

Slitting line production lines are essential in industries such as:

- Electrical Components (transformers, motors) for silicon steel strip processing.

- Automobile Manufacturing: Supplying precise metal strips for structural parts.

- Appliances: Cutting stainless steel or aluminum strips for housing components.

- Construction: Processing steel or galvanized strips for building materials.

- Packaging: Dividing materials for customized widths in coil packaging.

- Technological Advancements

Modern slitting lines increasingly incorporate:

- Intelligent Control: Real-time monitoring and fault diagnosis through IoT integration.

- Green Manufacturing: Energy-saving drives and reduced noise emission designs.

- Customization: Modular systems adaptable to client-specific production scales and material types.

- Conclusion

The slitting line production line embodies the synergy of mechanical precision, automation, and efficiency, enabling industries to achieve cost-effective, high-quality metal strip processing. As technological advancements continue, slitting lines will further evolve to meet the growing demands of intelligent factories and sustainable manufacturing.

This equipment’s reliability and versatility make it a cornerstone in modern metalworking, driving innovation across multiple sectors.

Contact Information (Optional if required):

For more technical details or customized solutions, contact me

|

|

|

|

|

|

|

|

| No |

Model |

Sheet Thickness(mm) |

Coil(ton) |

Coil Width(mm) |

Speed(m/min) |

Capacity(kw) |

Area(㎡) |

| 1 |

LM-2-650 |

0.1-2.0 |

10 |

150-650 |

0-150 |

130 |

4*15 |

| 2 |

LM-2-850 |

0.2-2.0 |

10 |

200-850 |

0-200 |

150 |

5*16 |

| 3 |

LM-2-1300 |

0.2-2.0 |

20 |

400-1300 |

0-200 |

250 |

7*18 |

| 4 |

LM-2-1600 |

0.3-2.0 |

20 |

600-1600 |

0-200 |

280 |

8*20 |

| 5 |

LM-3-1300 |

0.6-3.0 |

20 |

400-1300 |

0-200 |

280 |

7*22 |

| 6 |

LM-3-1600 |

0.6-3.0 |

25 |

600-1600 |

0-200 |

300 |

8*22 |

| 7 |

LM-6-1600 |

2.0-6.0 |

30 |

600-1600 |

0-100 |

320 |

8*28 |

| 8 |

LM-8-1800 |

2.0-8.0 |

35 |

600-1800 |

0-80 |

400 |

8*35 |

| 9 |

LM-12-2000 |

3.0-12.0 |

35 |

800-2000 |

0-60 |

500 |

10*45 |